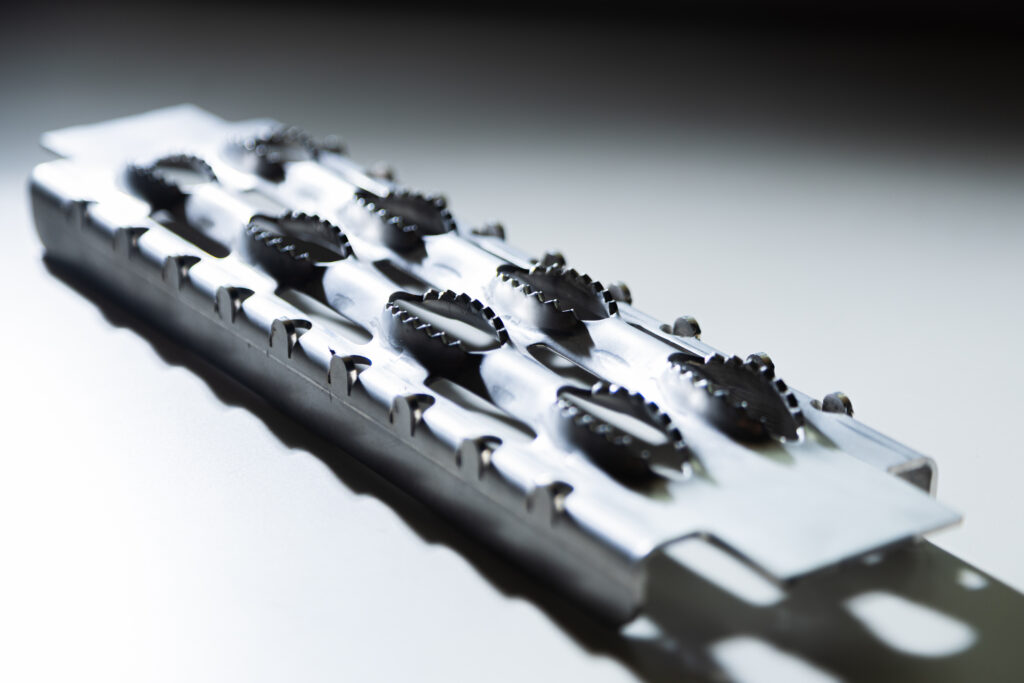

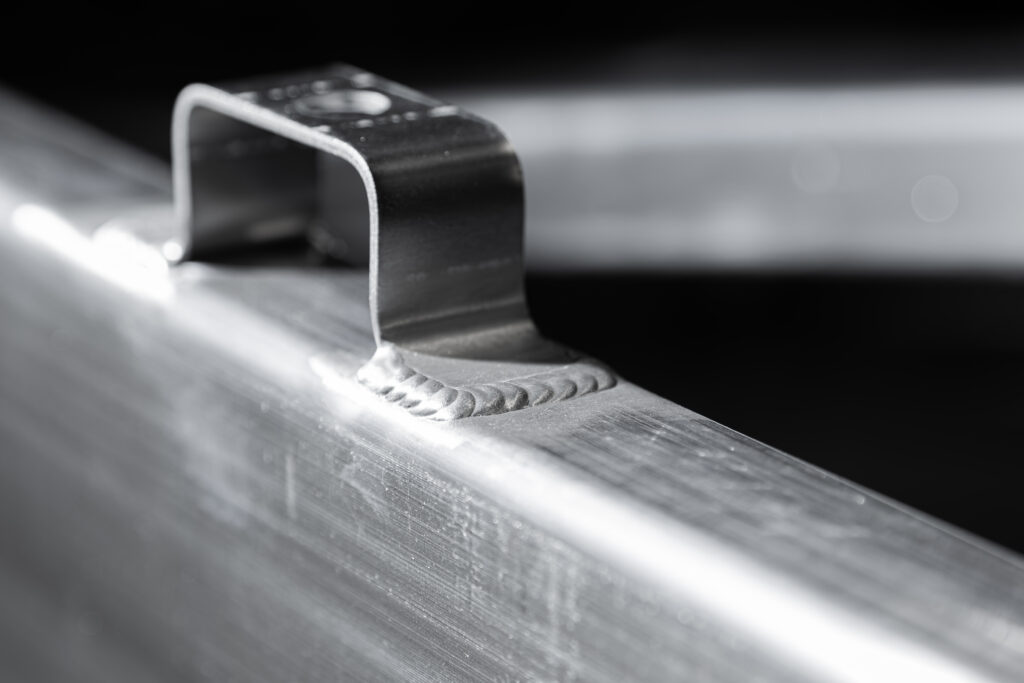

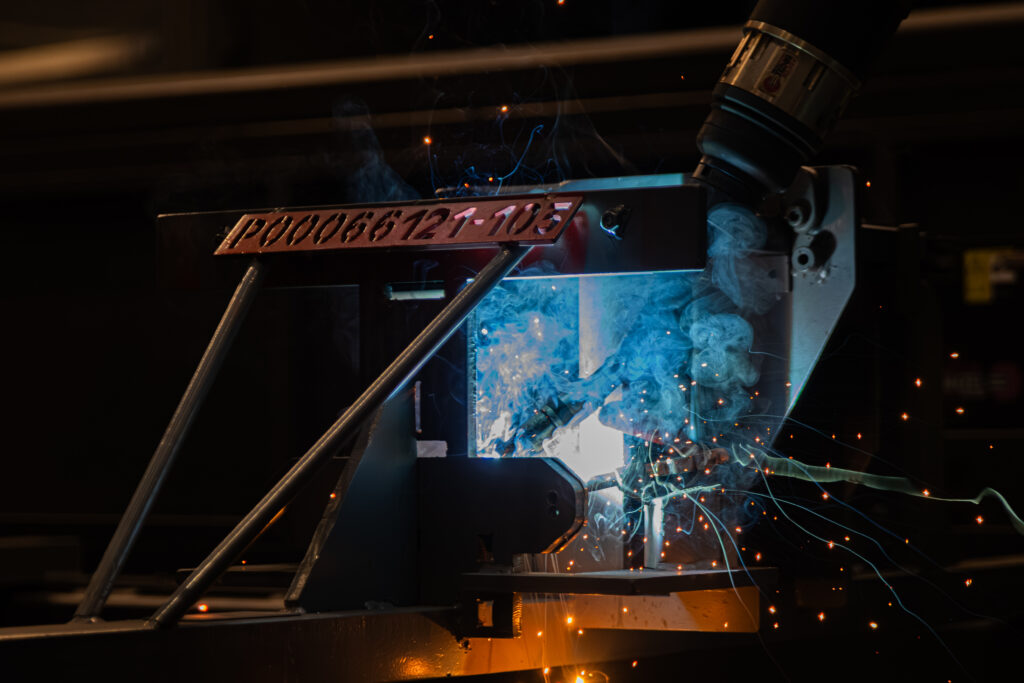

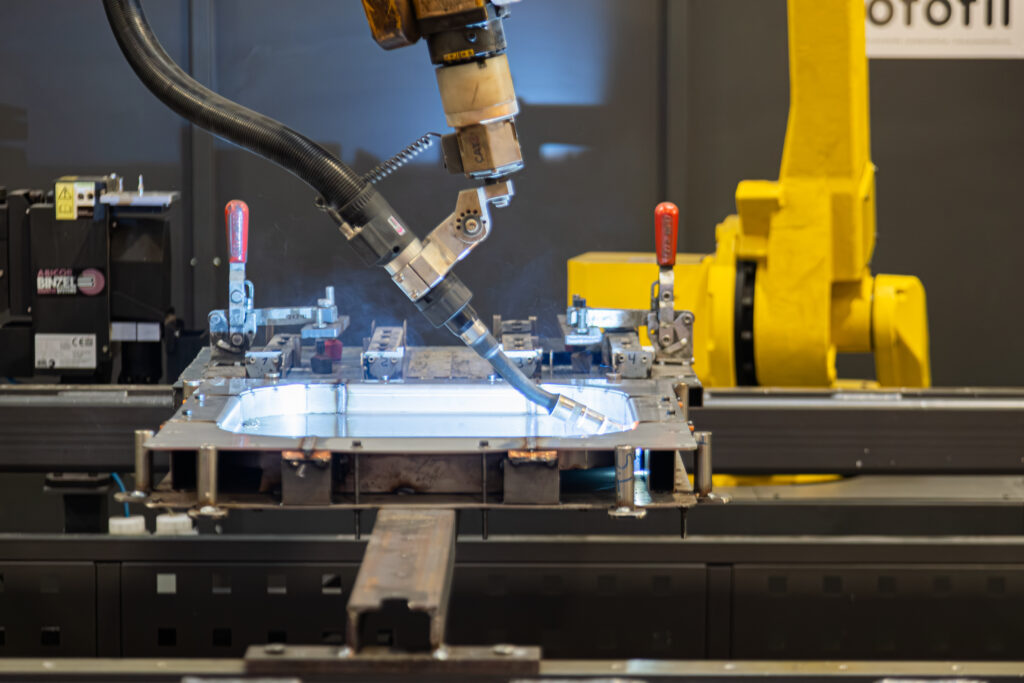

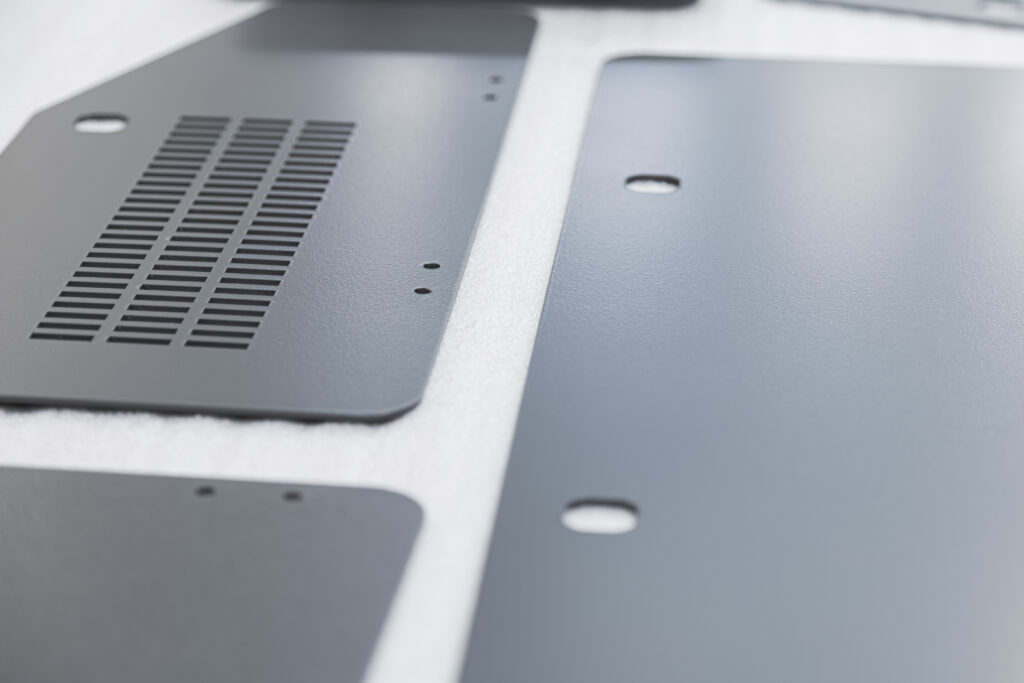

The manual welding is one of the key processes at Herdit, together with robotic welding, and constitutes a pillar of our production capacity. We have MIG, MAG and TIG machines, operated by approved personnel, working in the following areas sections separated by material: steel, stainless steel and aluminum.

For large parts we have specialized areas with 8-ton and 5-ton cranes and rotating supports that facilitate the handling and safe positioning of components. Our activity is supported by certifications such as EN 15085-CL1 for the railway sector, ISO 3834-2 and rigorous quality control through visual inspection, magnetic particle and liquid penetrant testing.

Continuous investment in technology, certifications and approvals guarantees the following precise, reliable welds that comply with the most demanding standards in each industry.